The EN 779 standard will be canceled completely mid of 2018, and ISO 16890 will be used as a new standard for Air Filter. The main change in standard allows the user to make the filter choice much more precise according to the needs of the users. Ulpatek Filtration has taken pioneering steps to inform the sector about its ISO 16890 standard by giving its brokers and business partners priority to Turkish and English information brochures.

About Air Pollutants

Airborne pollution sources are various which can be from natural sources like volcanos, thermal sources, pollens, sand storms and from industrial life like factories, automobile emissions, jet fuels, garbage dumps etc.

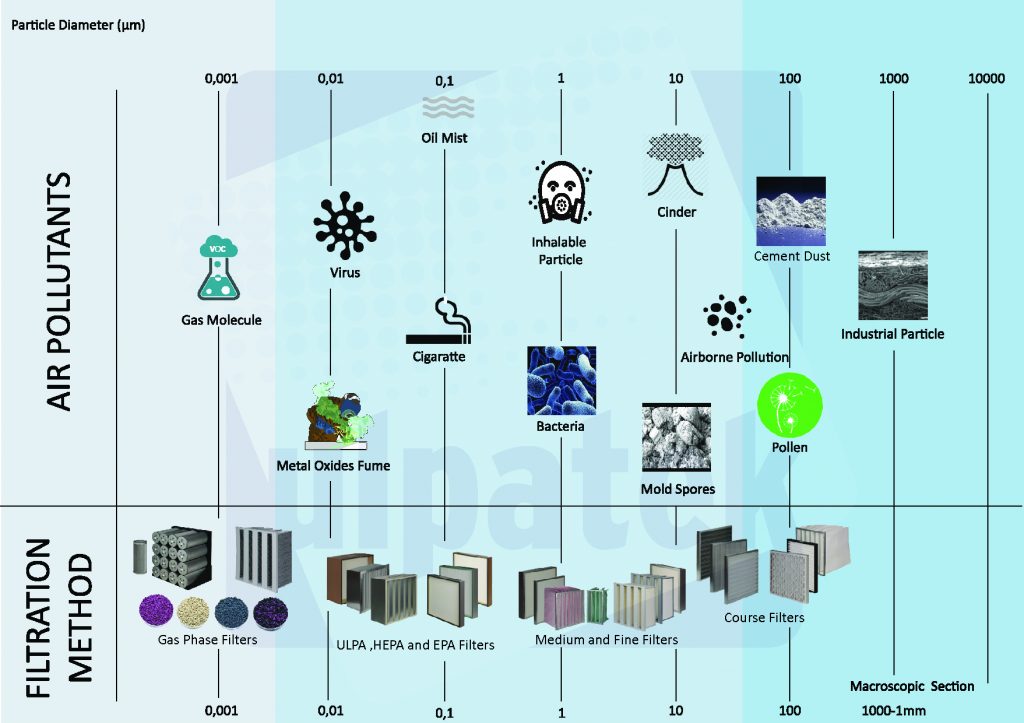

Pollutants are divided in to three physical conditions as solids, liquids and gases. Effective pollution control can be easily made by particulate and gas phase filtration. These filtration methods and applications are defined at EN779, 15016890, EN1822, ASH RAE 62.1 and ISA-71.04 standards. Airborne pollutants comparison chart shows size differences related particulate and gas phase filtration.

In order to apply the control methods for the gas phase pollutants, we have to know the pollutants and it’s effects. Main airborne pollution effects;

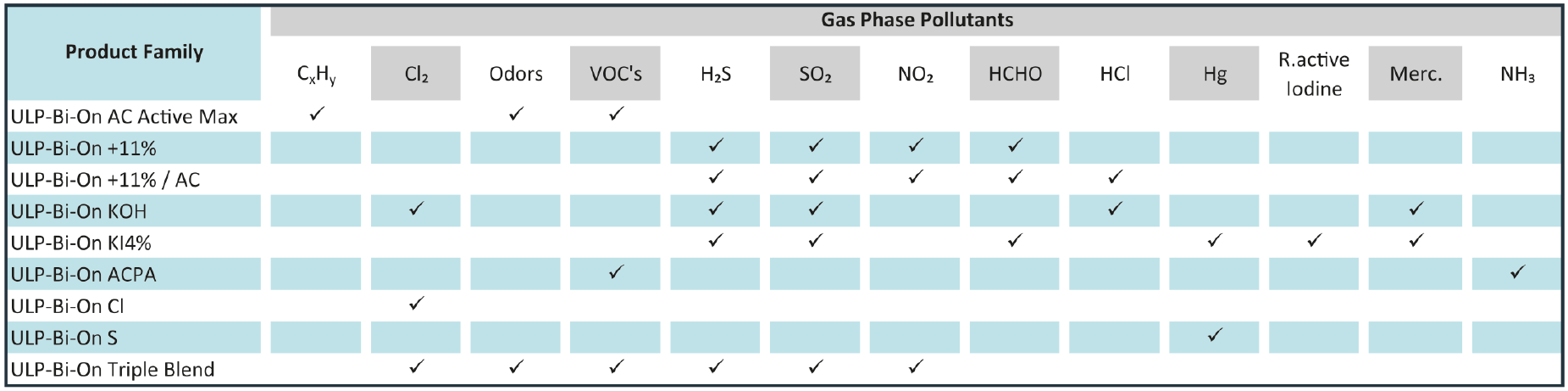

Ulpatek has various type of media which are selected according to the target pollutants.

Gas Phase Filtration

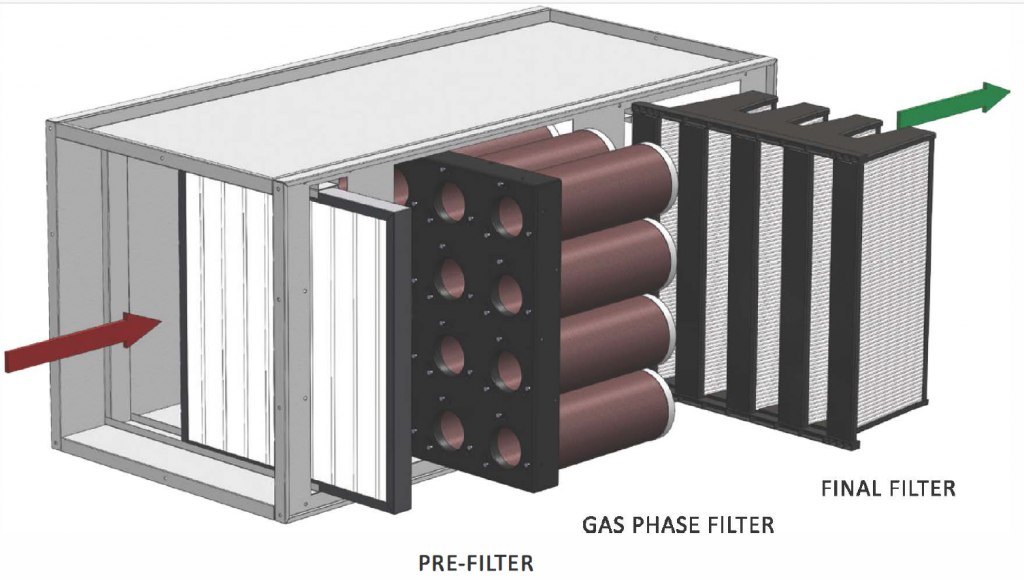

Gas phase filtration and particulate filtration work together for acceptable indoor air quality in controlled environments. Gas pollutants are filtered with Ulpatek’s gas phase air filters which are produced from one or mix filter media. Particulate pollutants are controlled with particulate filters which are mentioned in related standards ascourse, fine and absolute filters.

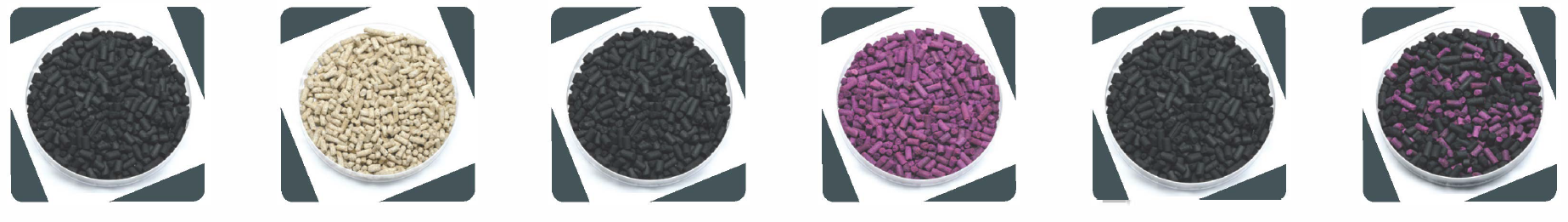

Gas phase filter media (pellets) generally are produced using carbon, zeolite, alumina or coconut-based media. Gas phase filtration occurs with the two different methods which are physical and chemical.

Gas pollutants are filtered on media surface with weak van der Waa/’s forces in physical method. That works also reversibleafter the removal capacity saturate.

Gas pollutants reacted to media’s surface via chemical bonds in chemical method. Chemical adsorption is irreversible.

Medias

ULP-Bi-On KOH

• Potassium Hydroxide

• Greatest purity and

bigger surface area

• Broad spectrum of

gas removal

ULP-BI-On Cl

• Sodium Thiosulphate

• Chlorine and acid gases

removal

ULP-Bi-On K/4%

• Potassium lodure

• Formaldehyde and

organic aldehydes

removal

ULP-Bi-On +11%

• Potassium Permanganate

• lrreversable removal

ULP-Bi-On AC Active Max

• Thermally activated

bituminous carbon

• No impregnates

• High gas removal

capacity

ULP-Bi-On Triple Blend

• Contains a 50:25:25 blend, respectively of

ULP-Bi-On KOH,

ULP-Bi-On AC Active Max,

ULP-Bi-On +6%

Cartridges and modules are the most popular gas phase filter application types in air filter equipment.

For local applications drum and indoor air cleaner devices are used for gas removal and indoor air quality.

Industrial Applications

Corrosion Control

Petrochemical Refinery

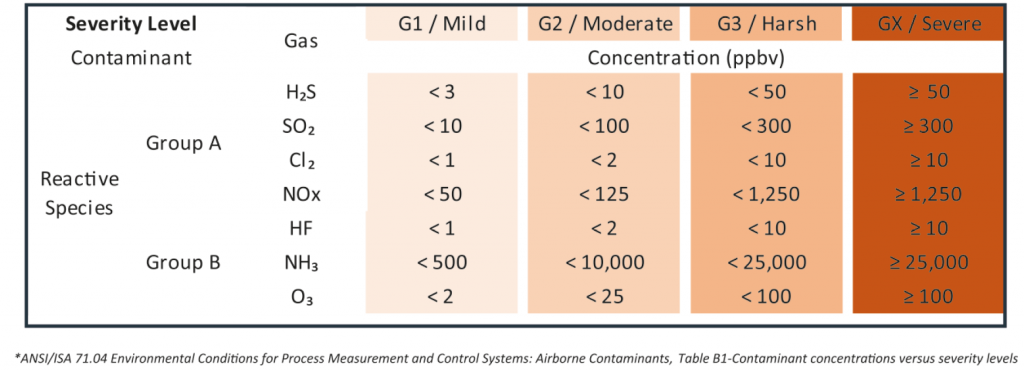

Process control systems, data centers and other rooms that have instrumentation which has to be environmental controlled must supply Gl classification according to ISA requirements. Achieving room ventilation design requirement must supply a minimum room pressurization of 1-3 air changes per hour and recirculationof 6-12 air changes per hour. Temperature is typically 22°C (±2°C) with humidity lower than 50% relative humidity. Tightness of the room is also another parameter while defining the design parameters. In addition to these parameters, hazardous pollutants are main parameter which must be removed from the enclosed space, According to the ANSI/ISA 71,04, contamination concentration levels are defined as follows.

Microelectronics

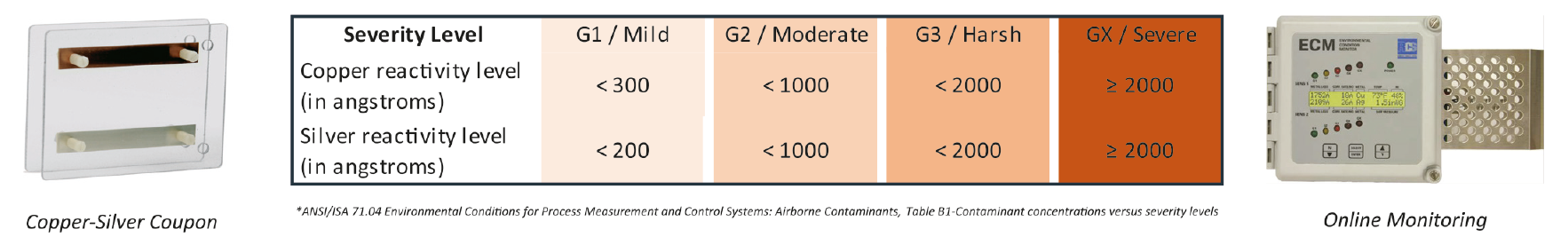

Monitoring for gas phase air filters is made by passive monitoring or on line monitoring.

Passive Monitoring: It is made with copper-silver coupons which must be used at the site with 30-90 days periods for defining remaining life and design parameters. Online Monitoring: It has an instant measurement of gas contamination. Particulate Filters Monitoring: Differential pressure gages are used for filter life monitoring.

Odour & Toxic Gas Control

Monitoring for gas phase air filters is made by passive monitoring or online monitoring. Toxic gas scrubbing is generally needed for filtration and neutralizing of chlorine(CIJ, sulfur dioxide(SO,) or ammonia(NH3)

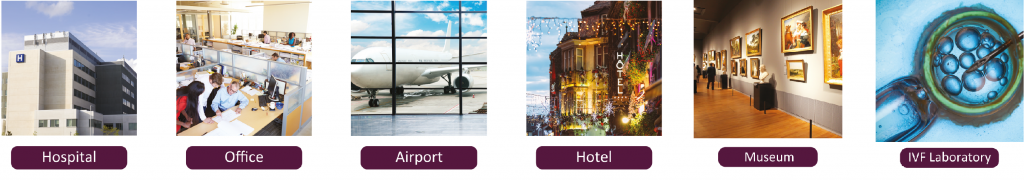

Indoor Air Quality

People usually spend their time in closed spaces like offices, schools, shopping malls, restaurants, cafes, hospitals, hotels, factories etc. Air pollution continuously increase due to the urbanization and industrialization. That’s why controlling airborne pollutants is critical to maintaining sufficient indoor air quality. There are particulate and gas pollutants in the environment. The pollution sources are from outside (the automobile emissions, kitchen exhaust, industrial factories) or from inside (as cleaning aerosols, bio effluents, furnishing, printings etc.) of the building. Particulate and gas pollutants must be filtered for sufficient indoor air quality.

(Supply Sufficient Indoor Air Quality)

Indoor Air Quality

Indoor contaminants are controlled with minimum required airflow “34m3 /h x person” according to ASHRAE’s “Ventilation Rate Procedure” Thus, outdoor air requirement can be reduced to “8,Sm3/h x person” according to the IAQ Procedure of AHRAE’s Standard 62.1.

Sick Building Syndrome (SBS)

Increasing real estate market prices made offices, high rise buildings more populated. Some buildings are surrounded with sick building syndrome due to the change of user requirements and insufficient HVAC designs.

Inadequate ventilation has a lot of parameters, but the most important parameter is the contamination control. Gas phase and particulate filtration help the buildings for recovering from the sick building syndrome.