ISO 16890 standardizes and provides a scientific approach to this process. Selecting air filters based on the ISO 16890 standard is important for improving indoor air quality and the efficiency of HVAC (Heating, Ventilation, and Air Conditioning) systems. Members of the Eurovent Association, which includes filter manufacturers playing a significant role in the Europe, Middle East, and Africa (EMEA) market, have published the document ‘Eurovent REC 4/23.’ This document provides recommendations for selecting filters to achieve the required indoor air quality according to ISO 16890 standards, drawing upon the work of the World Health Organization (WHO). To achieve the desired indoor air quality, the outdoor air particle concentration values have been categorized based on general ventilation and industrial usage. The required supply air (SUP) quality is obtained through recommended filtration efficiency to attain the desired indoor air quality.

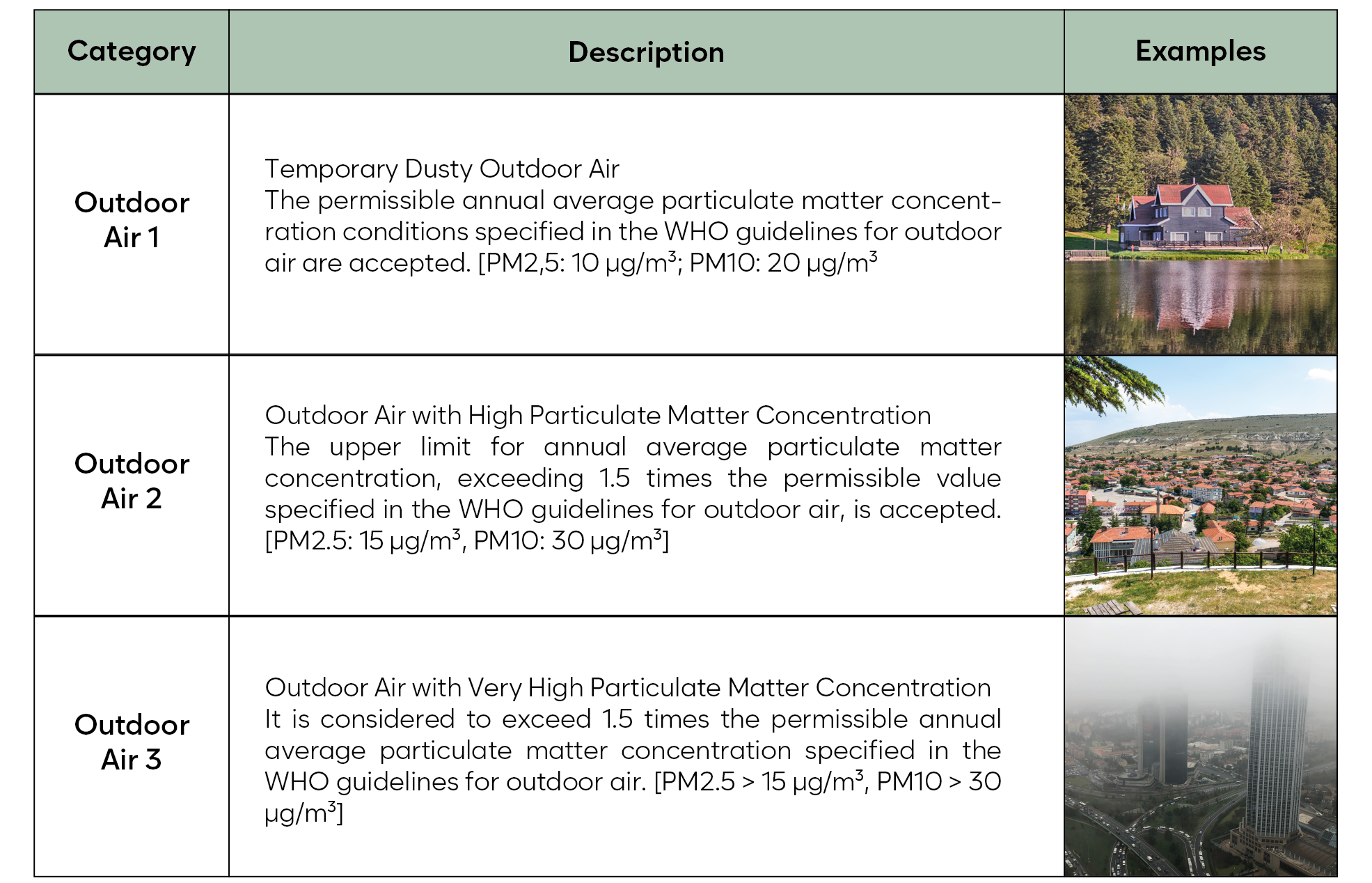

- In Eurovent REC 4/23, outdoor air (ODA; Outdoor Air) is divided into three groups.

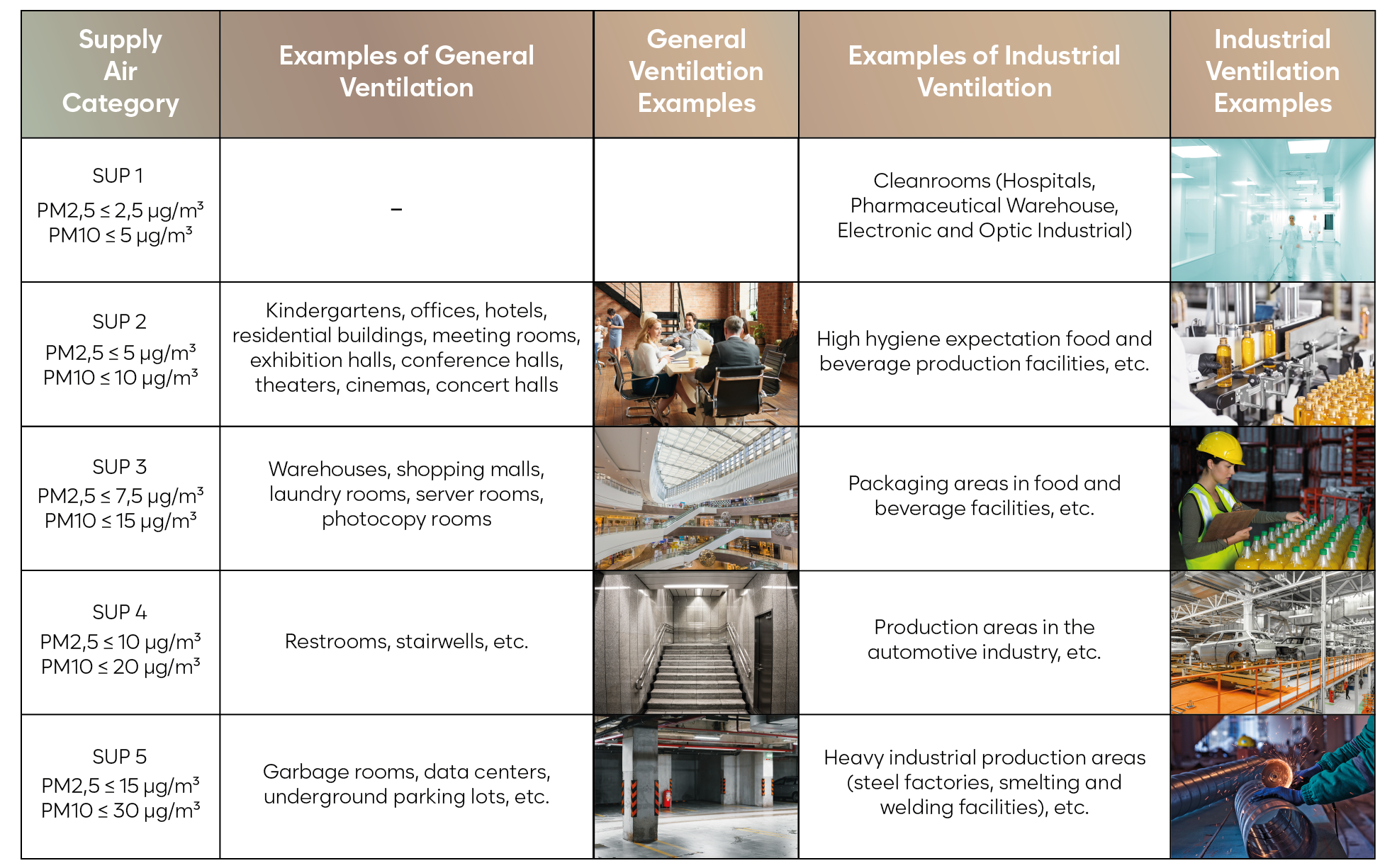

- In Eurovent REC 4/23, indoor supply air (SUP) is classified into five categories.

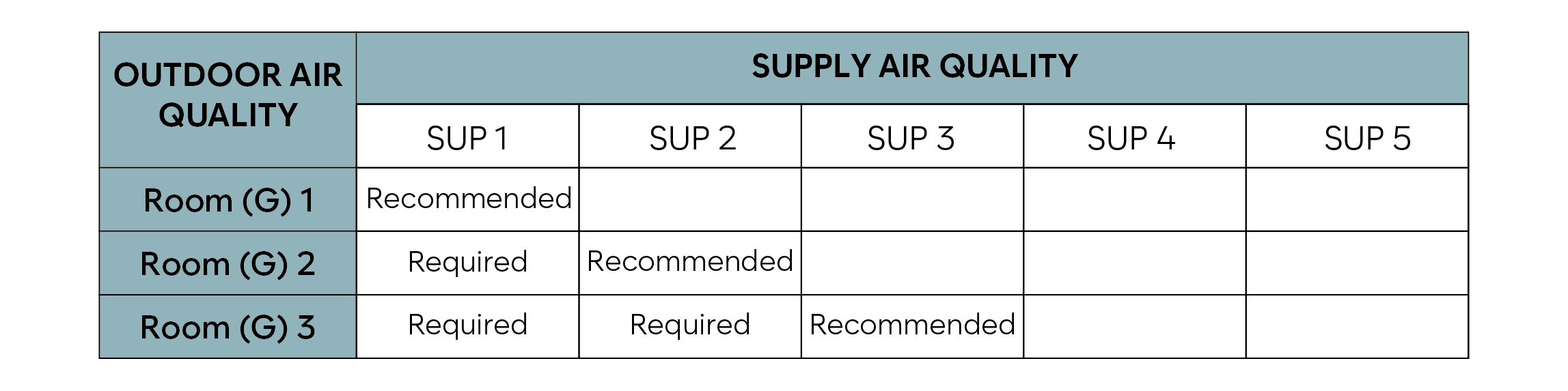

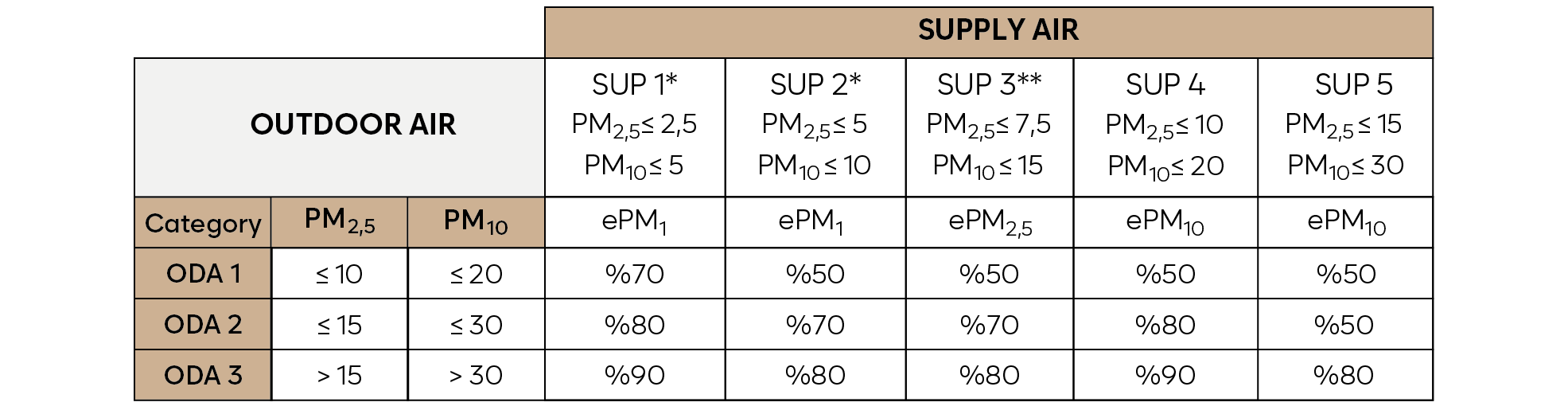

- The selection of filters that will provide the required efficiency according to the WHO guidelines is made by utilizing the outdoor air (ODA) and supply air (SUP) categories.

Table 1: Recommended min. ePMx filtration efficiencies depending on ODA and SUP category. Annual mean PMx values in μg/m³

* Minimum filtration requirements ISO PM1 50% refer to a final filter stage

** Minimum filtration requirements ISO PM2.5 50% refer to a final filter stage

EN ISO 16890 RATED FILTER CLASSES MEETING RECOMMENDED MINIMUM EFFICIENCY

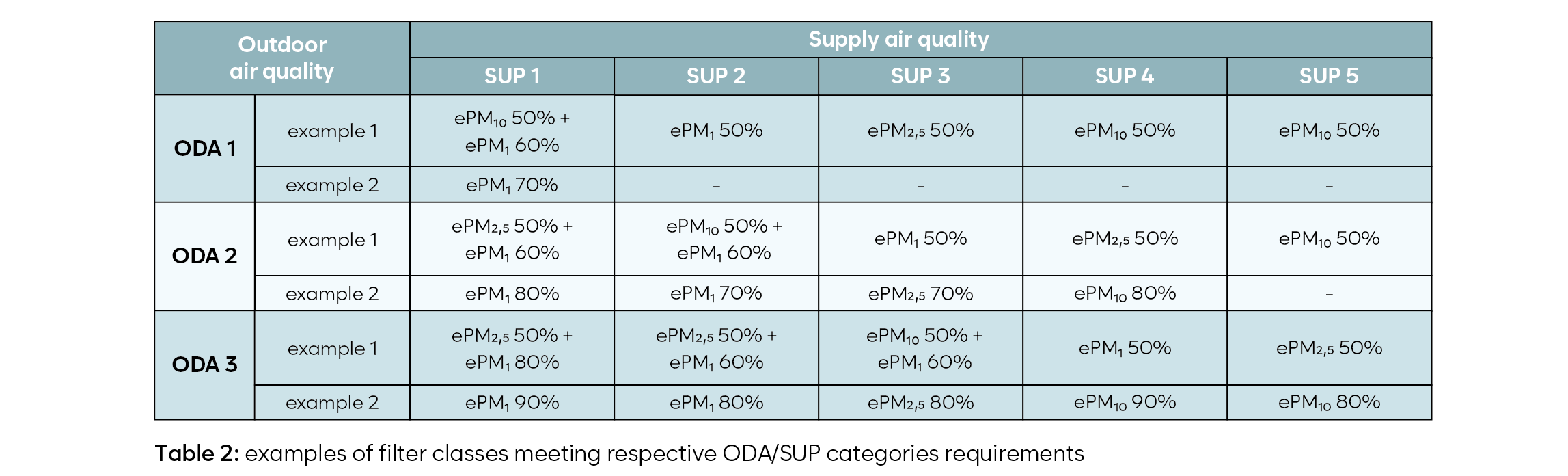

The recommended minimum filtration efficiency given in table 1 can be reached by applying alternative suitable filter classes (1 stage filtration) or various combinations of filter classes (multi-stage filtration).

This provides for the optimisation of a filtration system in terms of different criteria but especially the energy efficiency. Optimisation of the energy efficiency can be easily performed by joint consideration in the selection both the efficiency of particle separation and the Eurovent energy rating of respective filters.

An actual filtration efficiency can be determined directly based on ISO rating of a filter (if considered SUP category refers to the rated ePM group), efficiencies for other than rated ePM fractions, available in the technical data sheet of a filter, and additionally for multi-stage filtration – by means of the formula for combined filtration efficiency presented in chapter 5. To facilitate tentative selection, in table 7 below some examples of classes meeting recommended filtration efficiency for respective ODA/SUP categories were presented. It must be stressed this table is not exhaustive and it is recommended to contact a filter supplier for optimal selection.

Filtration is not only intended to ensure indoor air quality but also to protect HVAC systems. Therefore, the efficiency of the first-stage filter should be at least 50% at ePM10. In applications where humidification is performed, the efficiency of the air leaving the humidification cell should be at least 65% at ePM2.5. Another important parameter to consider when taking into account all the filter selection recommendations for achieving the desired air quality is the cost of energy consumption. From an energy efficiency perspective, filter models with lower initial pressure drop, a larger filtration area, and longer operational life under the same operating conditions compared to their counterparts should be preferred. End-users and operators can make improvements in energy savings by following the recommendations made by filter manufacturers regarding energy efficiency according to Eurovent REC 4/21-2018.

According to the conditions specified in the EN 16798-3:2017 standard, the combined use of particle filters and gas-phase filters is recommended for situations where outdoor air (ODA) conditions are not suitable and the desired supply air (SUP) conditions need to be met.

The selection of air filters made according to the ISO 16890 standard helps protect process equipment, ventilation ducts, fittings, and products. Especially, filters commonly used in building heating, ventilation, and air conditioning applications reduce particle matter concentration, improve indoor air quality, and significantly safeguard human health.