EN 1822, a European standard, provides a detailed classification system for HEPA and ULPA filters based on their filtration efficiency and ability to capture particles of various sizes. It outlines testing methods such as the leak test, the efficiency test, and the scanning test to ensure the filters meet their specified performance criteria.

ISO 29463, on the other hand, is an international standard that was derived from and is largely harmonized with EN 1822. It consists of a series of standards (ISO 29463-1 to ISO 29463-5) that cover the general requirements, test procedures, performance classification, and marking of HEPA and ULPA filters in a global context. The purpose of ISO 29463 is to establish a uniform international standard, making it easier for manufacturers and customers to compare and select filters that meet their specific needs.

BS EN 1822-1: 2019 – High efficiency air filters (EPA, HEPA and ULPA) –

Part 1: Classification, performance testing, marking

This part of standard applies to high efficiency particulate and ultra-low penetration air filters (EPA, HEPA and ULPA) used in the field of ventilation and air conditioning and for technical processes, e.g. for applications in clean room technology or pharmaceutical industry. It establishes a procedure for the determination of the efficiency on the basis of a particle counting method using a liquid (or alternatively a solid) test aerosol and allows a standardized classification of these filters in terms of their efficiency, both local and integral efficiency.

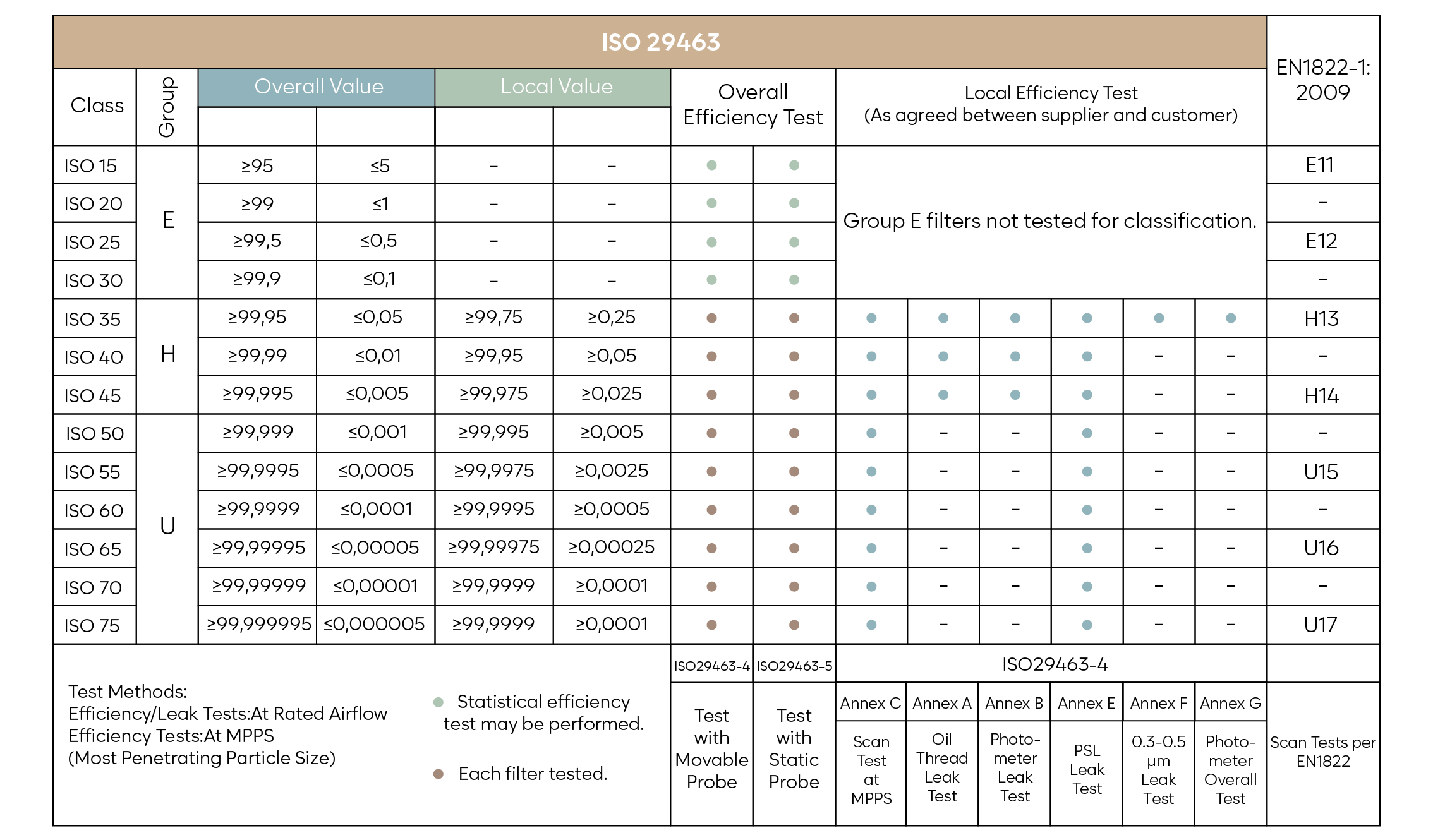

ISO 29463: New test standard for HEPA Filters

Originating from EN 1822, ISO 29463 introduces a novel standard that outlines 13 distinct filter categories, spanning from ISO 15 E to ISO 75 U. At the European level, the modified version of EN 1822-1 “Classification, performance testing, marking” will still be applicable. This revised standard will refer to sections 2-5 of ISO 29463. In simpler terms, EN 1822 will employ its unique classification system (Part 1) for air filters, while testing them according to ISO 29463 Parts 2-5. Nonetheless, there will be a slight variation in the leakage test methods specified by the two standards. While ISO 29463:2017 Part 1 details five methods, EN 1822 Part 1 only includes three.

EN 1822 Part 1 sets more stringent criteria for leak testing air particulate filters compared to ISO 29463. The former specifically prohibits the use of aerosol photometers. Concerning the allowance of PSL leak testing, the standard’s clarity is lacking. Part 1, Paragraph 7.3 mentions: “Possible aerosol substances include but are not limited to DEHS, PAO, and PSL”. Although this reference seemingly permits PSL testing, its practical significance is limited. PSL test procedures are highly expensive, resulting in their infrequent application.

As mentioned earlier, ISO 29463 retains the EPA, HEPA, and ULPA filter classifications outlined in EN 1822. The evaluation process in the new ISO standard also relies on particle arrestance at MPPS (Most Penetrating Particle Size), which represents the particle size at which an air filter exhibits minimal arrestance.

ISO 29463 begins with the filter group ISO 15 E, equivalent to filter class E11 as per EN 1822. This means there is no direct counterpart for the EPA filter class E10. In contrast, the test standard ISO 16890 features the filter group ISO ePM1 >95%, which serves as an equivalent to filter class E10.

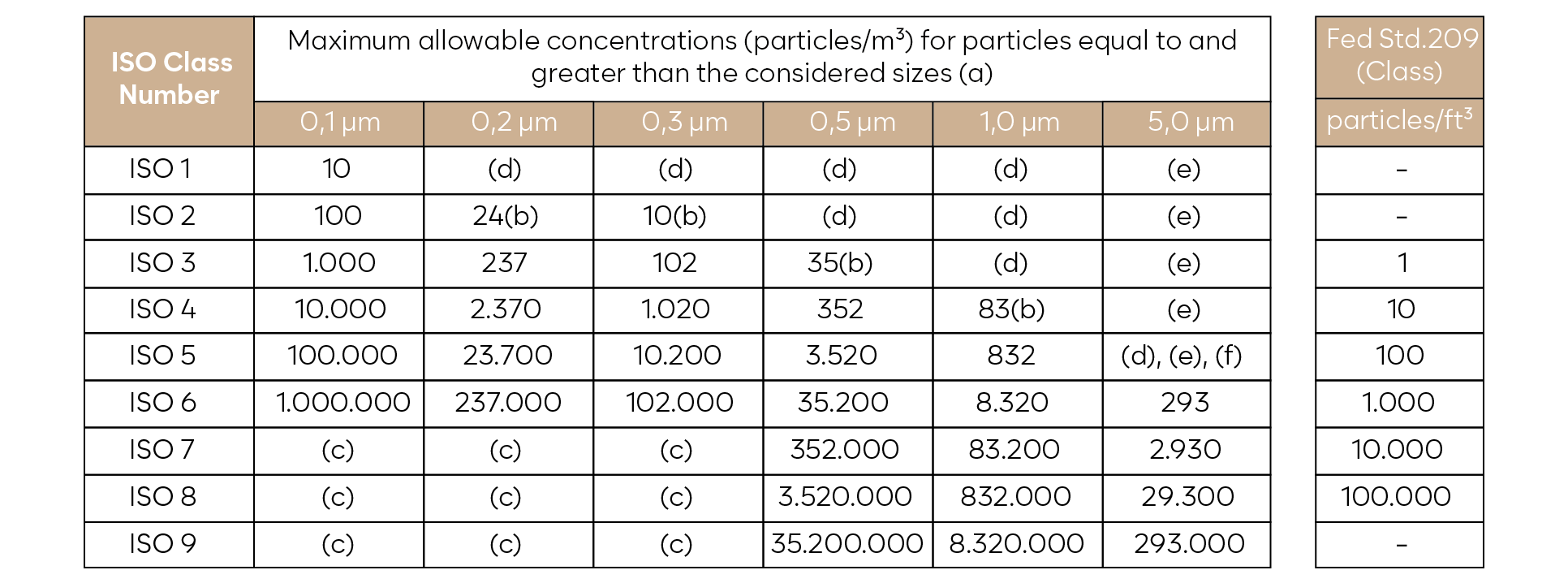

EN ISO 14644-1

ISO 14644-1 defines the classification of air cleanliness in cleanrooms and associated controlled environments exclusively in terms of concentration of airborne particles. Only particle populations having cumulative distributions based on threshold (lower limit) particle sizes ranging from 0,1 µm to 5 μm are considered for classification purposes.