Applications

- Final filter for hygenic type AHU’s

- Life science

- Healthcare

- Food & Beverages

- Operating theatre LF units

Highlights

- For high airflow rates (3000-4000 m³/h)

- High quality glass fiber media

- Guarented leak free

- Tested and certified acc to EN 1822 – ISO 29463 for H13 – H14

Technical Specifications

| Filter Standard: | EN 1822 and ISO 29463 | Max. Operating Tempature: | 80°C -120°C | |

| Filter Class: | E10 - E11 - E12 - H13 - H14 | Gasket: | EPDM, EPDM Flat continuous and PU Foam |

|

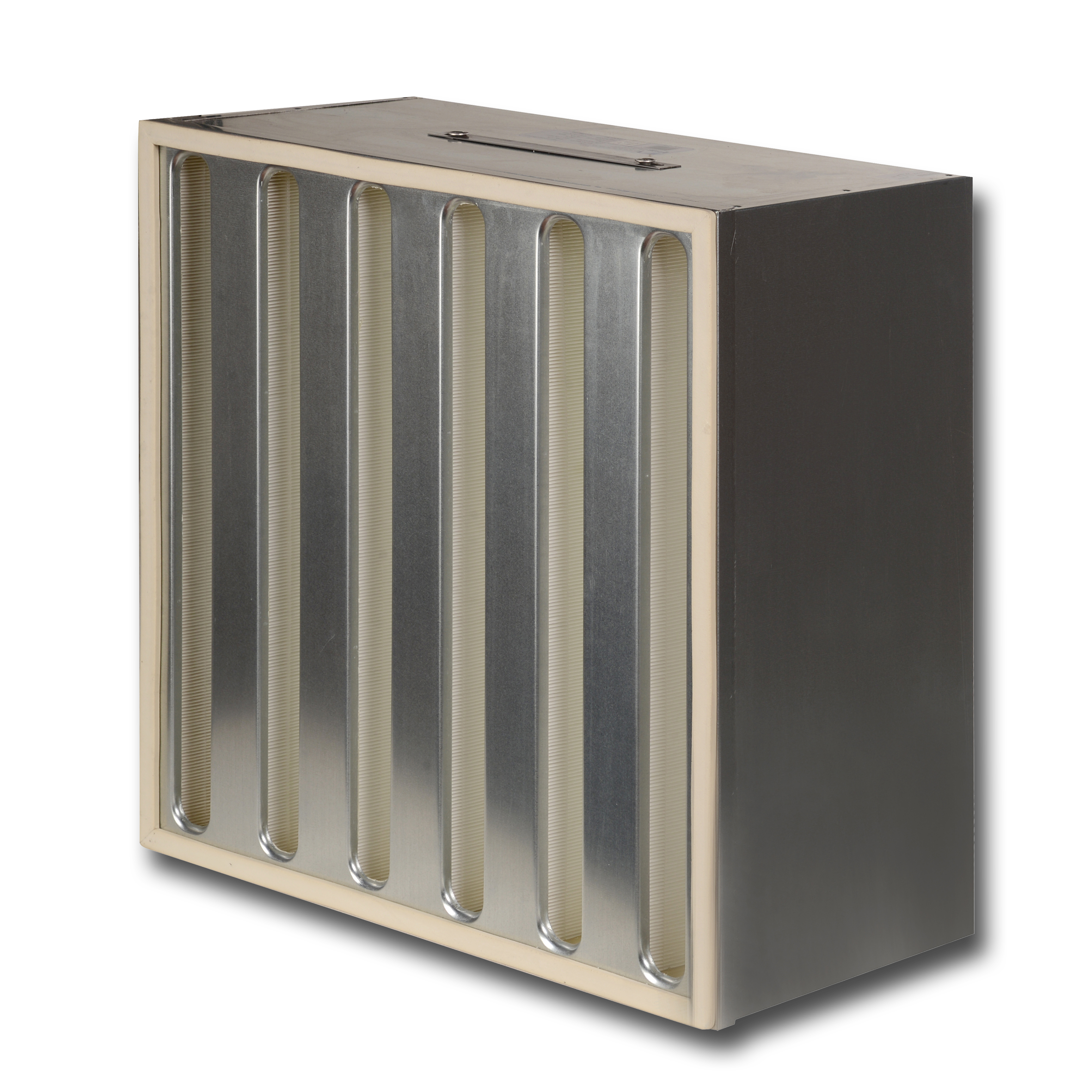

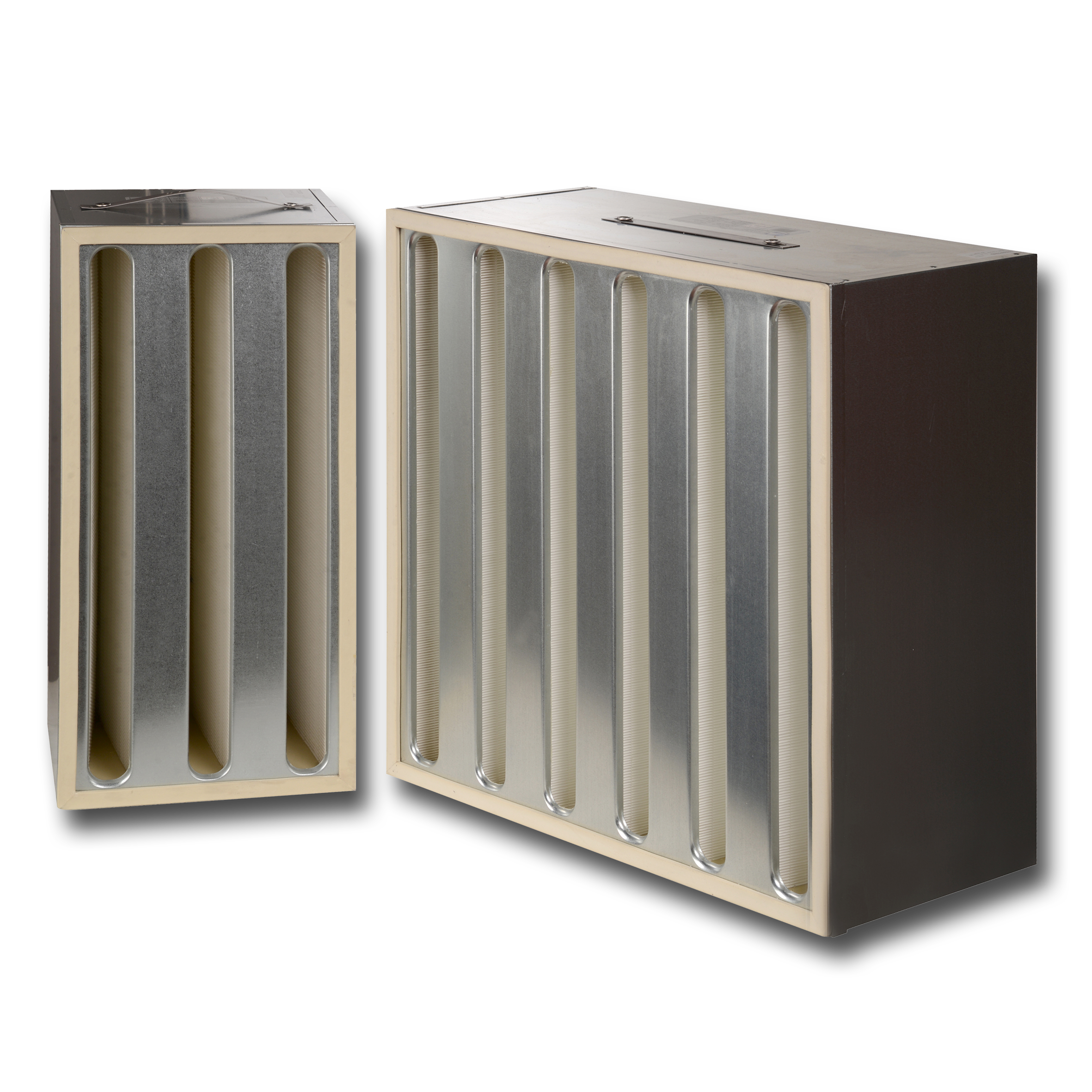

| Media: | High quality glass fibre | Design: | U-Module | |

| Frame: | Galvanized, Stainless Steel, Aluminium | Sealing Compound: | Two component polyurethane | |

| Rec. Final Pressure Drop: | Initial pressure drop x2, (max. 600 Pa) | Seperator: | Hotmelt |

Order Code

| Filter Type | Filter Class | Frame | Capacity | Dimensions (mm) | Gasket |

|---|---|---|---|---|---|

| HHV : High Capacity HEPA Filter with V-Module Design (Metal Frame) | E10 E11 E12 H13 H14 | A: Aluminium G: Galvanized Metal SS: Stainless Steel 304 SS316: Stainless Steel 316 | 30: 3000 m3/h 40: 4000 m3/h | 610x610x292 | P: Continuous Pu Foam PP: Pu Foam on Both Side E: EPDM Flat EE: EPDM Flat on Both Side C: Continuous Grey EPDM CC: Grey EPDM on Both Side |

| Filter Model | EN 1822 | ISO 29463 | Dimensions WxHxD (mm) | Filtration Area (m²) | Pleat Design | Nominal Airflow (m³/h) | Initial Pressure Drop (Pa) |

|---|---|---|---|---|---|---|---|

| HHV-H13-G-30-287-592-292-E | H13 | ISO 35 H | 287x592x292 | 11,9 | V-Module | 1370 | 270 |

| HHV-H13-G-30-305-610-292-E | H13 | ISO 35 H | 305x610x292 | 13 | V-Module | 1500 | 270 |

| HHV-H13-G-30-592-592-292-E | H13 | ISO 35 H | 592x592x292 | 24,5 | V-Module | 2830 | 270 |

| HHV-H13-G-30-610-610-292-E | H13 | ISO 35 H | 610x610x292 | 26 | V-Module | 3000 | 270 |

| HHV-H13-G-40-287-592-292-E | H13 | ISO 35 H | 287x592x292 | 16,9 | V-Module | 1880 | 290 |

| HHV-H13-G-40-305-610-292-E | H13 | ISO 35 H | 305x610x292 | 18,5 | V-Module | 2000 | 290 |

| HHV-H13-G-40-592-592-292-E | H13 | ISO 35 H | 592x592x292 | 34,8 | V-Module | 3760 | 290 |

| HHV-H13-G-40-610-610-292-E | H13 | ISO 35 H | 610x610x292 | 37 | V-Module | 4000 | 290 |

| HHV-H14-G-30-287-592-292-E | H14 | ISO 45 H | 287x592x292 | 13,7 | V-Module | 1415 | 300 |

| HHV-H14-G-30-305-610-292-E | H14 | ISO 45 H | 305x610x292 | 15 | V-Module | 1500 | 300 |

| HHV-H14-G-30-592-592-292-E | H14 | ISO 45 H | 592x592x292 | 28,2 | V-Module | 2830 | 300 |

| HHV-H14-G-30-610-610-292-E | H14 | ISO 45 H | 610x610x292 | 30 | V-Module | 3000 | 300 |

| HHV-H14-G-40-287-592-292-E | H14 | ISO 45 H | 287x592x292 | 18,3 | V-Module | 1880 | 300 |

| HHV-H14-G-40-305-610-292-E | H14 | ISO 45 H | 305x610x292 | 20 | V-Module | 2000 | 300 |

| HHV-H14-G-40-592-592-292-E | H14 | ISO 45 H | 592x592x292 | 37,7 | V-Module | 3760 | 300 |

| HHV-H14-G-40-610-610-292-E | H14 | ISO 45 H | 610x610x292 | 40 | V-Module | 4000 | 300 |

“Differential Pressure Tolerance ±10%”