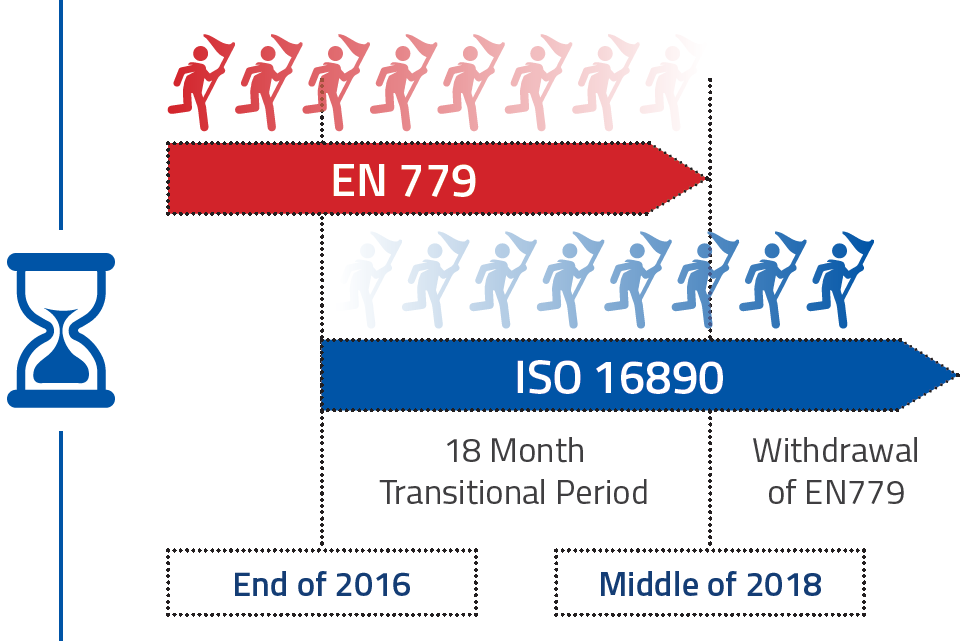

The EN 779 standard will be canceled completely mid of 2018, and ISO 16890 will be used as a new standard for Air Filter. The main change in standard allows the user to make the filter choice much more precise according to the needs of the users. Ulpatek Filtration has taken pioneering steps to inform the sector about its ISO 16890 standard by giving its brokers and business partners priority to Turkish and English information brochures.

Healt Effects Of Particulate Matter

Due to increased air pollution, the effects of particulates on human health has begun to be discussed in more detail. The results show that fine dusts are a serious health hazard that causes respiratory diseases and cancers.

Air filters for general ventilation are widely used in buildings for heating, ventilation and air conditioning applications. Air filters increase the indoor air quality by reducing the particulate matter concentration, thereby protecting human health considerably.

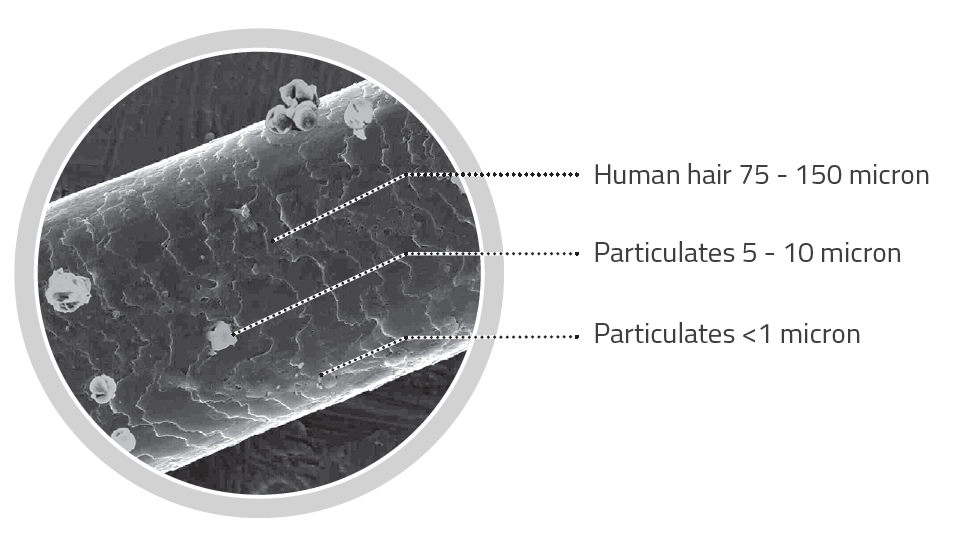

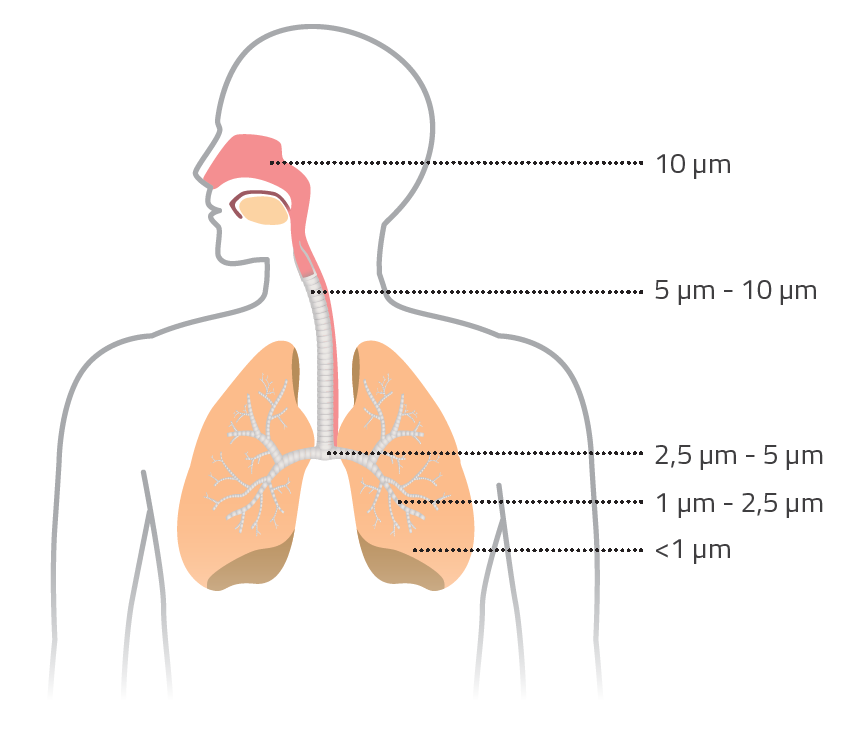

Particles larger than 10 μm in the atmosphere collapse very quickly and they can only hang in the air in strong wind near the source they are leaving. As an exception, some light fibers can stay in the air longer, despite their large diameter. Most particles larger than 10 μm in diameter can be seen with the naked eye in case of proper illumination and contrast. Under normal conditions, the minimum visible particle diameter is 30 μm and above.

Particles ranging in diameter from 5 to 10 μm or larger are separated and trapped by the upper respiratory tract. The intermediate sizes collaps on air channels of the lungs, then swallowed or coughed.

Particles ranging in diameter from 2.5 to 5 μm are likely to be retained in human lungs and are returned to the upper respiratory tract without falling into the depths of the lungs.

Particles ranging in diameter from 1 to 2.5 μm are retained in the bronchi and pose risks to human health.

The particles at 1 μm and below are small enough to interfere with the blood flow from the cell membranes of the alveoli.

Why Has ISO 16890 Been Launched Instead of EN779:2012

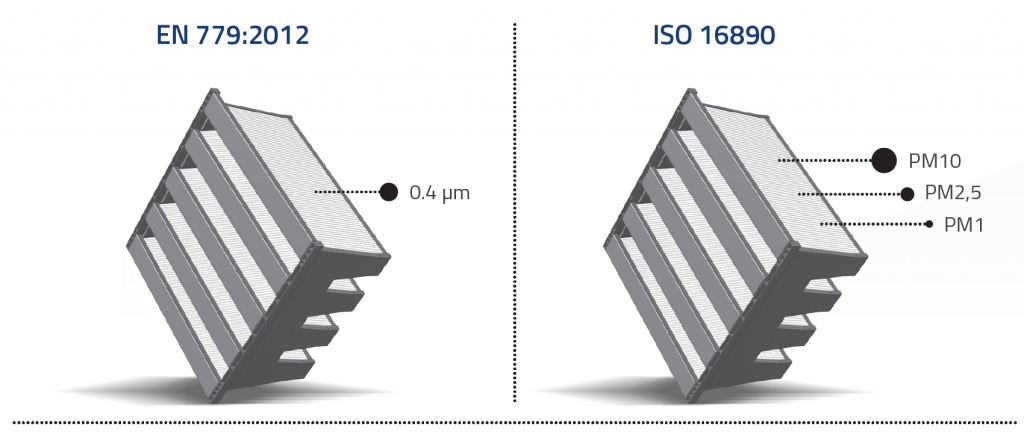

A synthetic powder called ASHRAE dust is used in the efficiency test of an air filter according to EN779: 2012 standard. The test is done by loading the filter with this powder in the laboratory environment. By this way, the efficiency of the filter can be calculated in the particle size of only 0.4 μm .

In operating conditions, filters are exposed to pollutants with a variety of different sized particulate. Therefore, the data obtained in the laboratory is insufficient to determine the performance of an air filter.

The EN 779: 2012 standard which is used in the classification of Coarse filters, Medium Filters and Fine Filters will be replaced by the ISO 16890 standard with an 18-month transition period.

With this change in standard, filter users will be able to choose the filter much more accurate according to their needs.

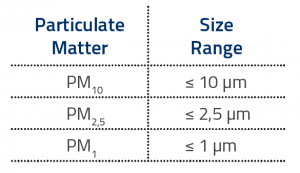

ISO 16890 standard considers for the particle size (Particulate Matter = PM) between 0.3 μm and 10 μm for efficiency evaluation.

ISO 16890 Test Procedure Step By Step

Step 1

Test procedure of the ISO 16890 standard begins with measuring the efficiency of an air filter at a particle size range of 0.3 μm to 10 μm.

Step 2

The Filter is subjected to an isopropanol vapor atmosphere to eliminate efficiency of electrostatic mechanism.

Step 3

Isopropanol vapor atmosphere conditioned Filter tested again to measure the minimum efficiency ePM1,min and ePM2,5,min

Step 4

Efficiency for each PM size is calculated by the mean of both conditioned and the conditioned filter.

Step 5

The efficiencies for ePM1 are calculated for the particle size 0,3 -1 μm , ePM2,5 for the particle size range of up to 2,5 and ePM10 for the particle size range of up to 10 microns.

Step 6

Calculated efficiency values are rounded to the nearest lower value according to the efficiency values in the ISO 16890 classification groups.

ISO 16890 Classifications

ISO ePM1

ePM1 95%

ePM1 90%

ePM1 85%

ePM1 80%

ePM1 75%

ePM1 70%

ePM1 65%

ePM1 60%

ePM1 55%

ePM1 50%

Requirement

≥50% Initial Efficiency

≥50% Discharged Efficiency

ISO ePM2,5

ePM2,5 95%

ePM2,5 90%

ePM2,5 85%

ePM2,5 80%

ePM2,5 75%

ePM2,5 70%

ePM2,5 65%

ePM2,5 60%

ePM2,5 55%

ePM2,5 50%

Requirement

≥50% Initial Efficiency

≥50% Discharged Efficiency

ISO ePM10

ePM10 95%

ePM10 90%

ePM10 85%

ePM10 80%

ePM10 75%

ePM10 70%

ePM10 65%

ePM10 60%

ePM10 55%

ePM10 50%

Requirement

≥50% Initial Efficiency

≥50% Discharged Efficiency

ISO Coarse

ePM10 45%

ePM10 40%

ePM10 35%

ePM10 30%

ePM10 25%

ePM10 20%

ePM10 15%

ePM10 10%

ePM10 5%

No discharge requirement

Reference particle sizes according to EN 779: 2012 and ISO 16890 standards

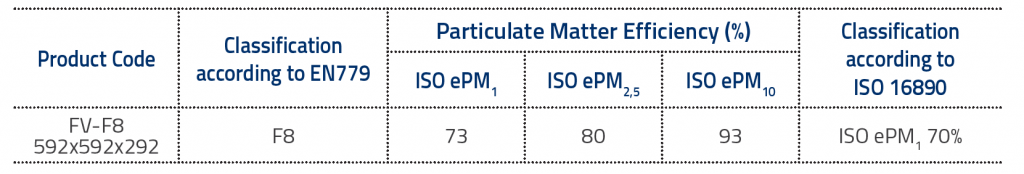

For example; According to the test result, the F8 class V-Compact Filter is classified as “ISO ePM1 70%”. This means that the filter seperates %70 of PM1 particles. The “e” stands for efficiency in combinition with the particulate matter (PM).

Comparison of EN 779: 2012 and ISO 16890 Standards

| OLD STANDARD EN 779 |

| Filter classes F7-F8-F9 M5-M6 G2-G3-G4 |

| • Average gravimetric arrestance • Average efficiency based on 0,4 μm particles • Minimum efficiency (F7-F9) • Dust holding capacity for synthetic test dust (ASHRAE) • Δp |

| The evaluation is carried out with a particle size of only 0.4 μm. |

| Determining of average efficiency/arrestance after loading synthetic dust. Mean of test measurements at 0,4 μm particulate size. |

| Distinction is made according to filter class. There is no detailed informations about particle size. |

| Filters chosen without regard to application. |

| Covers Europe (EN: European Standard). |

| NEW STANDARD ISO 16890 |

| Four ISO groups ISO ePM1 ISO ePM2,5 ISO ePM10 ISO Coarse |

| • Efficiency based on PM10, PM2,5 and PM1 • Dust holding capacity for synthetic test dust ISO A2/AC Fine • Initial gravimetric arrestance • Δp |

| The evaluation is carried out with a particle size from 0,3 μm-10 μm. |

| The efficiency is measured according to the particle range. Measuring efficiencies after 24 hours of IPA process. Calculating the «ePMx efficiency» with mean of test measurements. |

| Filter performance is determined according to particulate matter PM10, PM2,5 ve PM1. Detailed info about various particle sizes. |

| Application is taken into consider when choosing filter. |

| Global (ISO, International Standard Organization). |

*EPA, HEPA and ULPA class filters are also used in ventilation and air conditioning systems for clean rooms and similar applications. These highly efficient filters are classified and tested according to the current EN 1822: 2009 standard. The old EN 779 standard and the new ISO 16890 standard do not include EPA, HEPA and ULPA class filters.

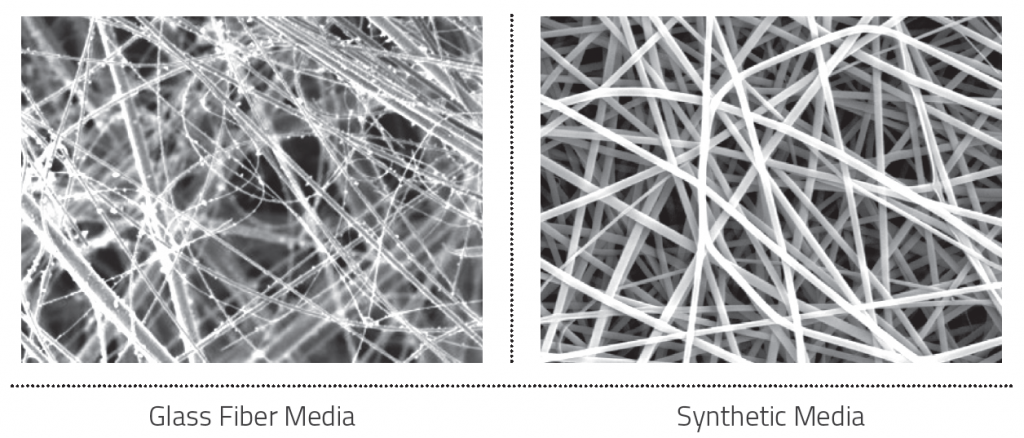

About Filter Media

The EN 779: 2012 standard has minimum efficiency values to be provided for F7, F8 and F9 filters. This is mainly because the synthetic fiber filter media shows very low efficiency in tests after removal of the electrostatic filtering effect with isopropanol. This is also the most important reason for recommending filters to the end users with glass fiber media instead of bag filters with synthetic fiber media. In addition to the ISO 16890 standard, the minimum efficiency value stands out as a more restrictive step. This situation; will help to replace bag filter produced with glass fiber media instead of the bag filter produced with synthetic fiber media.