Laminar Flow Units prevent operating zone from microbes, bacteria and other living organisms.

ISO 14644-1 (Definition: Controlled contamination environment “CleanRoom”)

“Room“

- In which the concentration of airborne particles is controlled

- Constructed and used in a manner to minimize the particles

- In which significant parameters such as temperature humidity and pressure, are controlled according to the requirements.”

Introduction

- The operating theatre ceiling is the most important part of a hospital ventilation system.

- Operation theatre type Laminar Flow Unites are in use to supply laminar flow around the operating table and zone. Laminar Flow Unites prevents operating zone from microbes, bacterium and other particles.

- These sophisticated systems are actually a combination of a variety of elements, air filter housings or filter grids, HEPA filters, priming illumination and air diffusers.

- Ulpatek Laminar Flow Units are improving the day-to-day safety of patients across the world.

In practice in Turkey, DIN 1946-4 standard is generally taken into consideration. According to DIN 1946-4 standard, the ranges of temperature, relative humidity and air velocity parameters mentioned in this standard should be under control at a range of 19–26 ºC, 30–60% and 0.23-0.30 m/s, respectively. At 1200 mm height from floor, desired the air velocity is at the range of 0.23-0.25 m/s

Operation theater type Laminar Flow Units are constructed from stainless steel. For filtration H13 / H14 HEPA filters with aluminum frames are used. A laminisator made of special taut silk fabric is used under the laminar flow unite, to achieve laminar flow. Laminisator is made of two parts with a special design that enables pendant lamp connection in the middle of the unit.

Specifications

- Montage and service easiness with high quality design

- DIN 4799 Standart sterility on partial and full capacities

- Hepa Filter Box with differential manometer connection ports and aerosol port

- Used High capacity HEPA filter (EN1822)

- Metal Frame H13 / H14 Filters connection side with sealing

- Pendant Lamp connection detail

- Separate seal leak test ports for each HEPA filter (in conjuction Hepa Filter Box with differential manometer with test groove)

Laminar Flow Unit Types For Operating Theatres

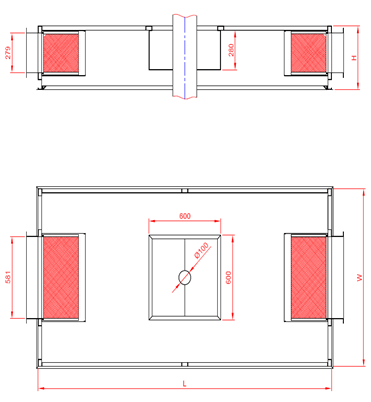

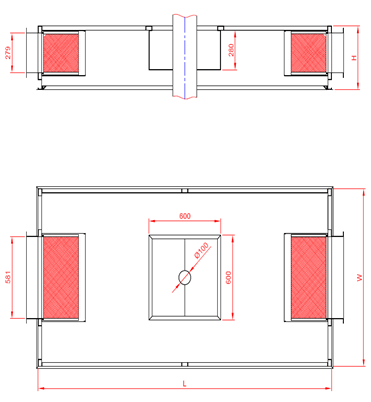

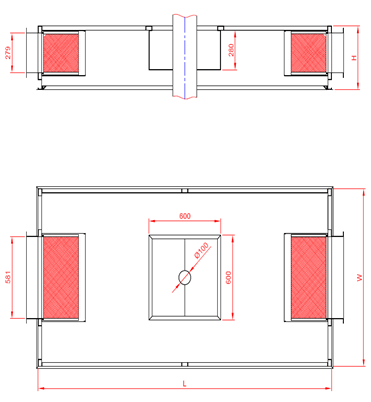

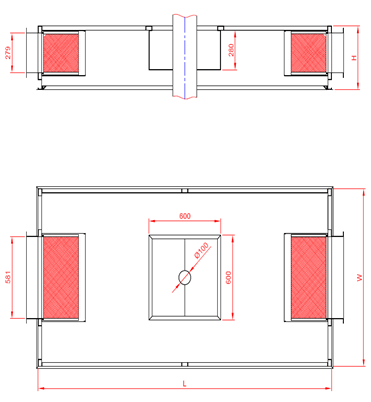

Laminar air-flow units with filters on side air inlets

Laminar air-flow units with filters on side air inlets

Laminar air-flow units with filters on side air inlets

Auxiliary clamping frames for filters are located on the casing side and can be moved in and out of the casing in the direction of air supply. This feature enables to utilize the space inside or outside the casing according to constructional requirements. The frame is clamped to the casing and allows to install probes that measure tightness of filter clamping.

Advantages;

- Easy installation

- Less filter replacement cost

- Minimum risk of leakage (Less filter surface

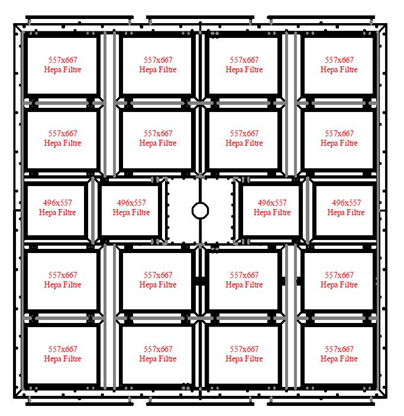

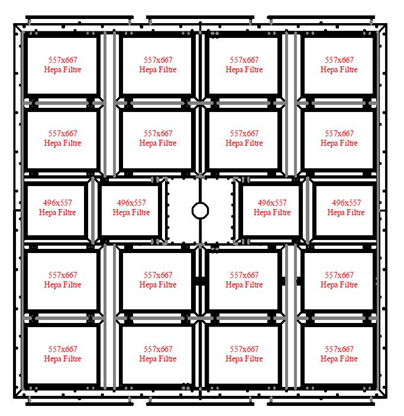

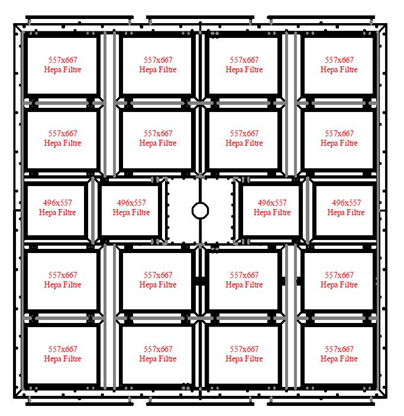

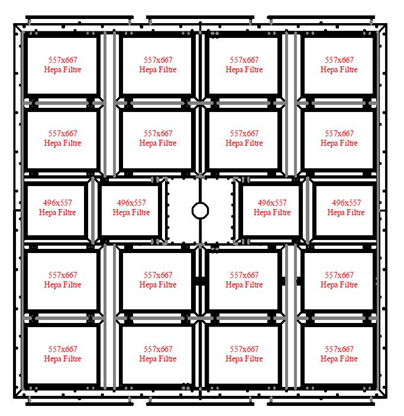

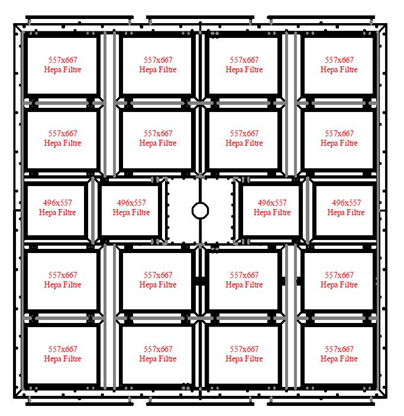

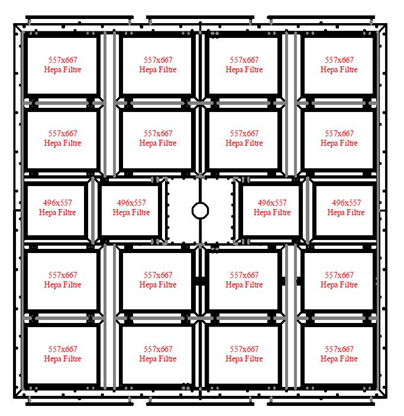

Laminar air-flow units with filters over the ceiling surface

- This laminar flow unit has more filtration surfaces and more filters than the other models.

- The higher filtration surface means lower pressure drop. But, the risk of leakage, the cost of filter replacement and the difficulty of filter installation increases.

- Filter change requires special sensitivity, the staff must be skilled and experienced in this regard.

- Since the filters are on the ceiling surface, the air velocity distribution will be more homogenous.